Dental LT Comfort Resin is a flexible, durable material that can be used to make comfortable, long-lasting occlusal splints and night appliances. Approved for skin contact, BioMed Durable Resin enables the manufacture of durable, biocompatible and impact-resistant medical instruments and devices.

Formlabs, the leader in 3D printing, this summer announced the launch of two new materials for dental and medical applications available for Form 3B, Form 3B+ and Form 3BL printers: Dental LT Comfort Resin and Biomed Durable Resin. The company is expanding its range of more than forty 3D printing materials to drive innovation and enable healthcare facilities, medical manufacturers and dental and orthodontic practices and laboratories to create bespoke devices.

‘With the launch of these two new materials, we are proud to expand our range of materials and enable dental and medical professionals to push the boundaries of 3D printing,’ said Guillaume Bailliard, President of the Healthcare Division for Formlabs.

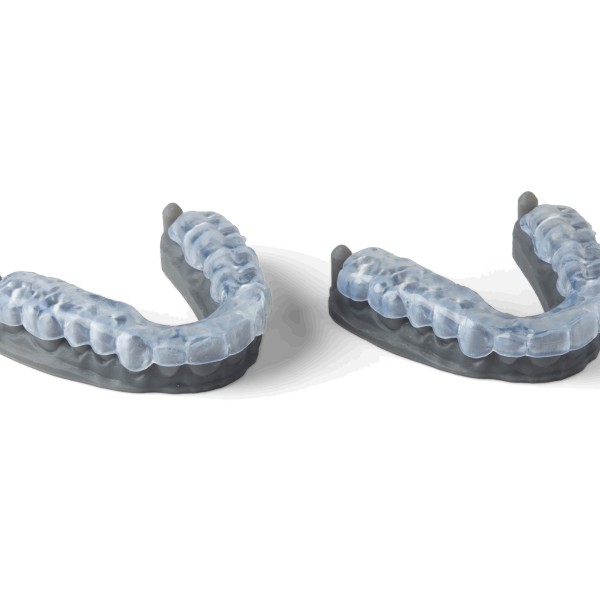

Dental LT Comfort Resin

Formlabs is launching Dental LT Comfort Resin, a new biocompatible 3D printing material that enables the manufacture of flexible splints and durable occlusal plates. This new material has been designed to offer patients high comfort, good adaptation and excellent resistance to wear. As a result, treatment can be improved by, for example, increasing patient compliance and reducing the number of follow-up visits. With this latest addition to its dental product range, Formlabs is continuing its mission to provide high-quality, affordable and easy-to-use materials to dental practices and laboratories.

EXERGUE 1: Dental LT Comfort Resin is a new biocompatible 3D printing material for making flexible trays.

‘When I was able to try out Dental LT Comfort Resin from Formlabs Dental, I was amazed,’ said Stephan Kreimer, Managing Director of Kreimer Dentallabor GmbH & Co. ’The pre-polished appearance and exceptional translucency of the resin straight out of the printer meant that post-processing time was considerably reduced. I was also impressed by its fracture resistance and flexibility, which ensure optimum comfort and make it an ideal choice for dental trays.’

BioMed Durable Resin

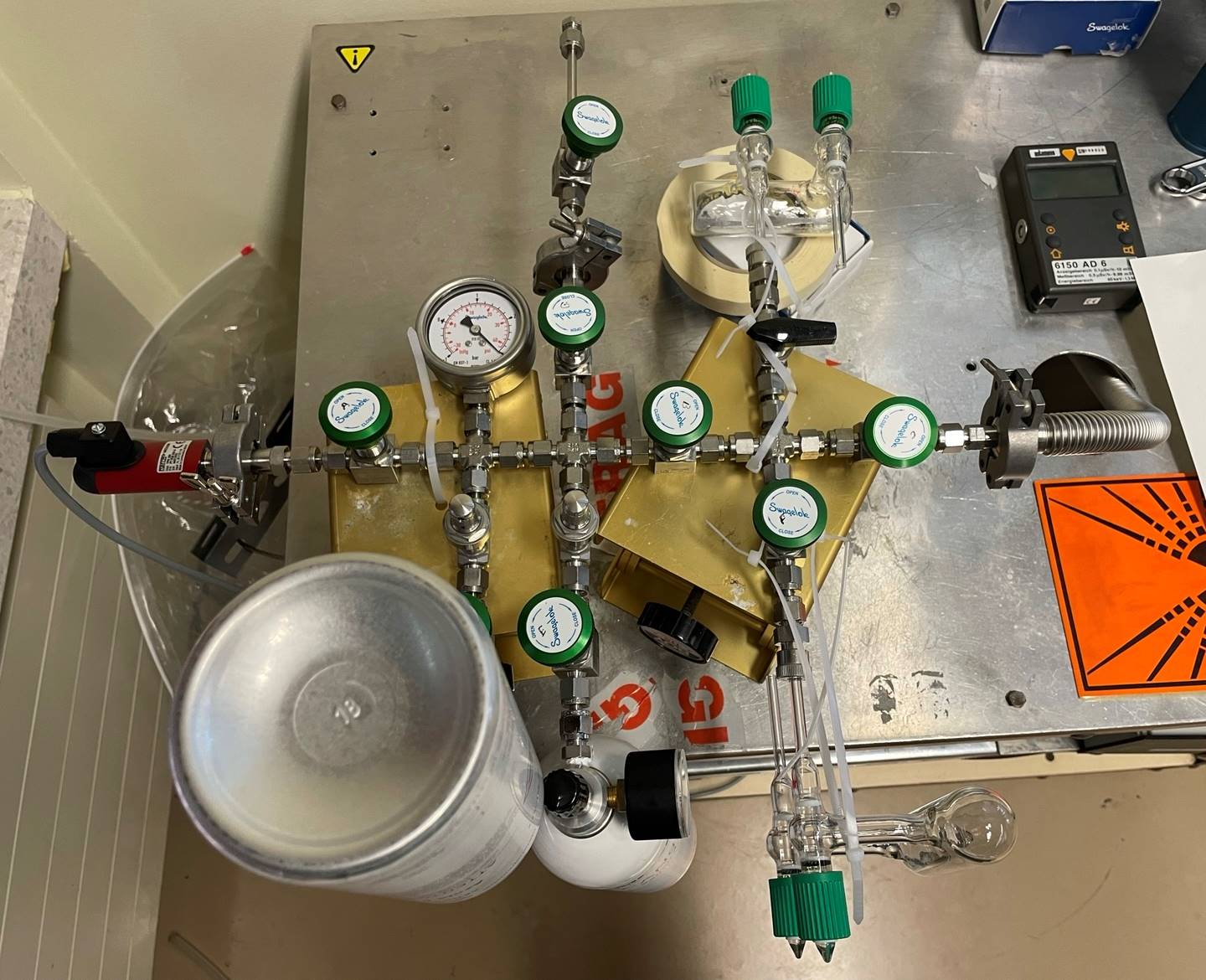

Formlabs’ biocompatible resins, in particular BioMed Clear Resin and BioMed White Resin, have been widely used to create medical devices ranging from surgical guides to anatomical models. To meet the demand for bespoke medical devices and instruments, Formlabs is now launching BioMed Durable Resin, a new formulation developed specifically to meet the need for a biocompatible material that can withstand impact, rough handling and pressure.

Patient-specific devices such as custom surgical guides have been shown to improve patient outcomes by 16%, and reduce complications by up to 30%. In addition, custom devices increase precision, reducing operating times and improving patient outcomes. BioMed Durable Resin opens up new possibilities for 3D printing in the healthcare sector. Its impact, chip and abrasion resistance, transparency and excellent surface finish make it ideal for making customisable surgical instruments that can be struck with a surgical mallet or shaken with a chop saw.

EXERGUE 2: BioMed Durable Resin opens up new possibilities for 3D printing in the healthcare sector.

TechFit is a PSI supplier that works with doctors to design and 3D print surgical instruments. CEO and co-founder Mauricio Toro uses BioMed Durable Resin to produce bespoke instruments that can withstand shocks, chips and abrasion. ‘We believe that Biomed Durable Resin is the ideal material for printing single-use, patient-specific surgical instruments,’ says Toro. ‘Its excellent mechanical properties offer greater design flexibility and access to a wider range of indications. It also retains the biocompatible properties required to achieve the best possible surgical outcomes.’

BioMed Durable Resin is a USP Class VI material manufactured in an FDA-registered, ISO 13485-certified facility. It can be used in applications requiring prolonged contact with skin and short-term contact with tissue, bone and dentin.

About Formlabs

Formlabs is paving the way for digital manufacturing so that everyone can create without limits. The company is headquartered in Somerville, Massachusetts and has offices in Germany, Japan, China, Singapore, Hungary and North Carolina.Formlabs 3D printing is the first choice of engineers, designers, manufacturers and decision makers worldwide.

Formlabs products include the Form 3+, Form 3B+, Form 3L and Form 3BL printers, which are based on an advanced form of stereolithography (SLA) called Low Force Strereolithography (LFS) 3D printing, the Form Wash and Form Cure post-processing solutions, the Fuse 1 SLS 3D printer and the Form Auto industrial production solution. With its Factory Solutions range for industrial users, Formlabs offers tomorrow’s factories the flexibility they need for demanding and scalable industrial applications. Formlabs is also developing its own range of high-performance materials that push the boundaries of 3D printing, as well as some of the best 3D printing software.

www.formlabs.com