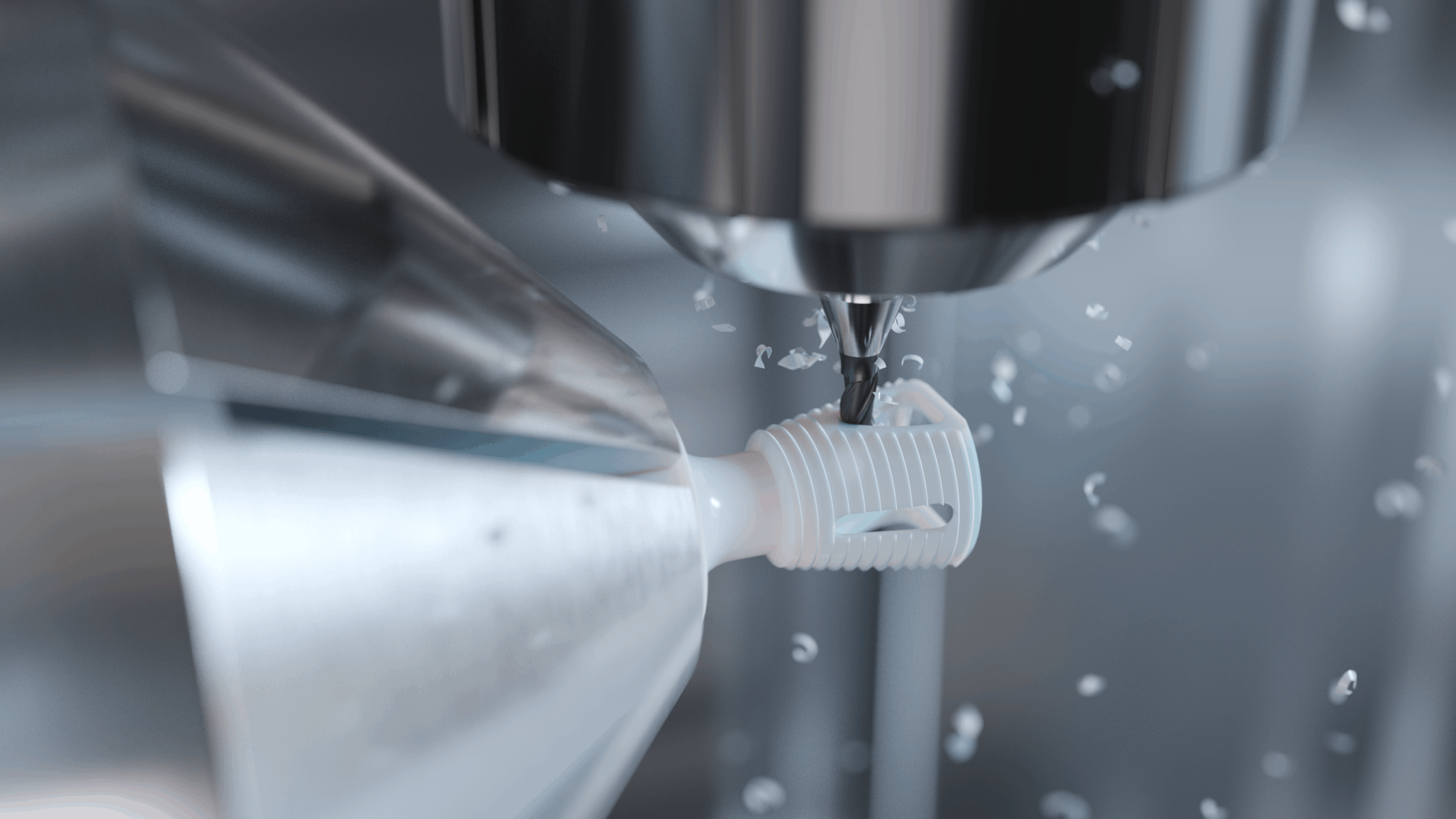

In the demanding world of micro-precision, challenges are intensifying. Watchmaking, medical, and microtechnology sectors face evolving materials and technical demands. Machining lead-free alloys or platinum is becoming increasingly complex, impacting quality and profitability. Louis Bélet SA offers an innovative solution: Excalibur.

The Precision Game Changer

Excalibur is more than just a tool; it’s an answer to the most intricate machining challenges. This range, designed to push the boundaries of productivity and quality, represents a major advance for micro-precision professionals.

Productivity through Excellence

Excalibur tools, made from solid polycrystalline diamond (PCD), offer unmatched abrasion resistance and durability. No more machine downtime or constant adjustments. Thanks to a laser-ground cutting geometry, Excalibur ensures consistent precision, even after thousands of parts. This innovation reduces waste and improves dimensional stability and surface finish.

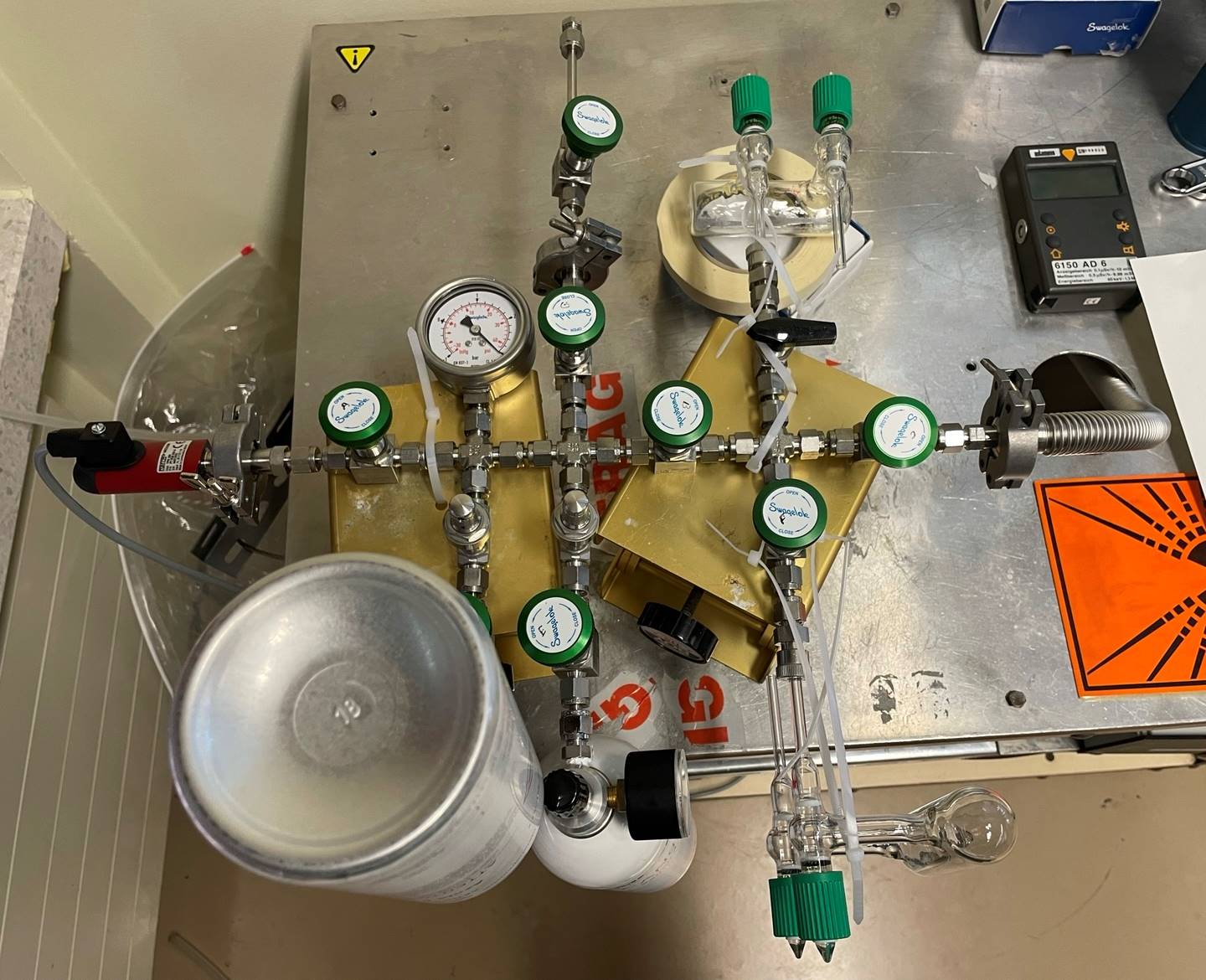

Technology and Expertise

The result of years of research and rigorous testing at Louis Bélet SA, each end mill and drill is specially designed for abrasive materials, guaranteeing perfect geometry. Wear resistance, reduced burr formation, and cutting consistency allow for optimized production cycles and increased performance.

Proven Success

Tests in real-world conditions with our partners have proven Excalibur’s effectiveness: extended tool life, increased productivity, and a minimal scrap rate. Like you, those facing these challenges, have optimized their processes and improved their output.

Your Advantages with Excalibur

- Productivity: Less machine downtime.

- Precision: Consistent quality guaranteed.

- Innovation: Solid PCD and laser ground geometries.

- Results: Proven performance in production.

With Excalibur, transform your productivity, secure your processes, and ensure the impeccable quality that defines your reputation. Excellence is within reach.